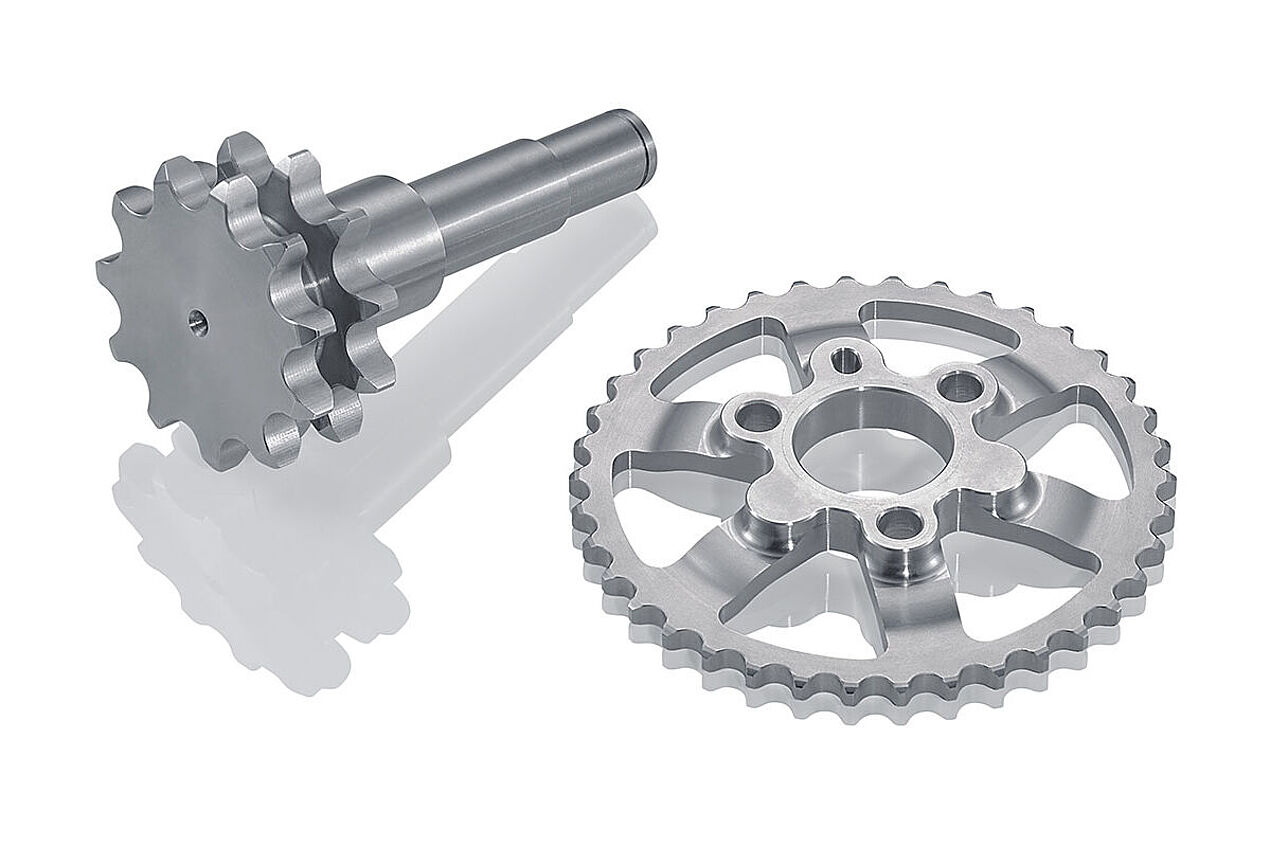

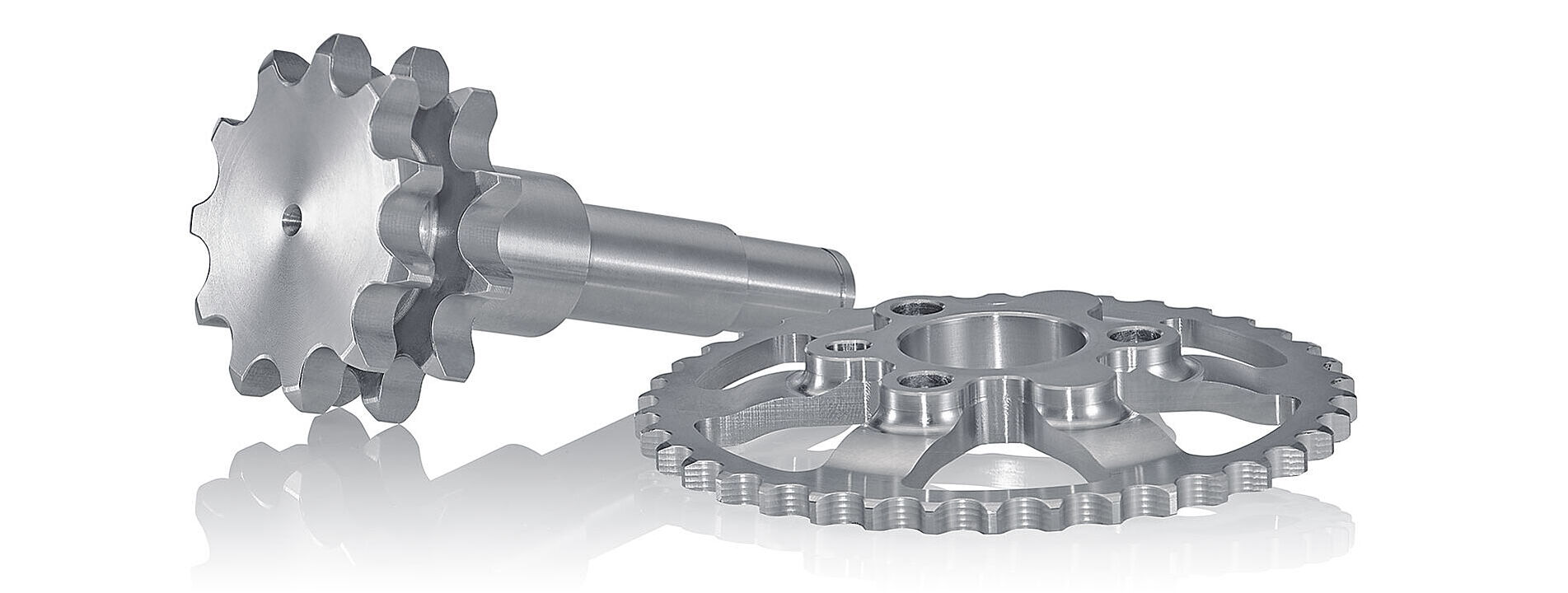

Sprocket/Sprockets

A sprocket is a mechanical element shaped like a toothed disk which, together with a chain, is used for the transmission of power as part of a drive system. There are two basic types of sprockets.

The first type is the classic sprocket with gear-like teeth which transfers power via roller chains. This is the type used in chain drives. The sprocket gear and the chain form a drive mechanism to harness and transmit power. A typical example of this is the chain drive of a bicycle. It is important that the sprocket teeth fit into the roller chain links precisely and smoothly so that the required driving power can be generated. These sprockets are standardized in accordance with DIN 8192 and are usually designed as disks, sometimes having a flange on one side. The minimum number of teeth is 15, otherwise the chain drive would not function smoothly and vibration would occur.

Depending on loads and intended usage, these sprockets can be designed as single, dual or triple sprocket gears. Dual and triple chain drives are more suited for handling high levels of traction.

These chains are commonly used in the automotive sector to drive camshafts.

Sprockets made of steel or brass are typically used for this purpose.

Sprockets are also used with link chains. These sprockets differ in form and shape as well as sprocket size, and they are made of steel or stainless steel.

Sprockets are also used with link chains. These sprockets differ in form and shape as well as sprocket size, and they are made of steel or stainless steel.

In addition to powering shafts, sprockets can also be used with transport chains, anchor chains and conveyor chains. These sprockets are versatile and can be used in many different applications because they do not put a heavy load on bearings. The circumferential speeds are also much lower than those of sprockets used with roller chains. This depends on the design.

Link chains are distinguished by their oval shape, with the individual links forming 90° angles between each other. These chain links are not standardized. These sprockets are available as disks for specific links, and they may have single or dual hubs.

When choosing the right chain, attention must be given to the power to be transferred, along with the operating conditions and the revolutions per minute of the smaller sprocket. These are the basic criteria for selecting just the right sprocket.

Before they are put into operation, the chains are lubricated and should be inspected and maintained at regular intervals to ensure a long service life.

If you have any questions about sprockets, please contact us and profit from our know-how and experience!