Quality without compromise

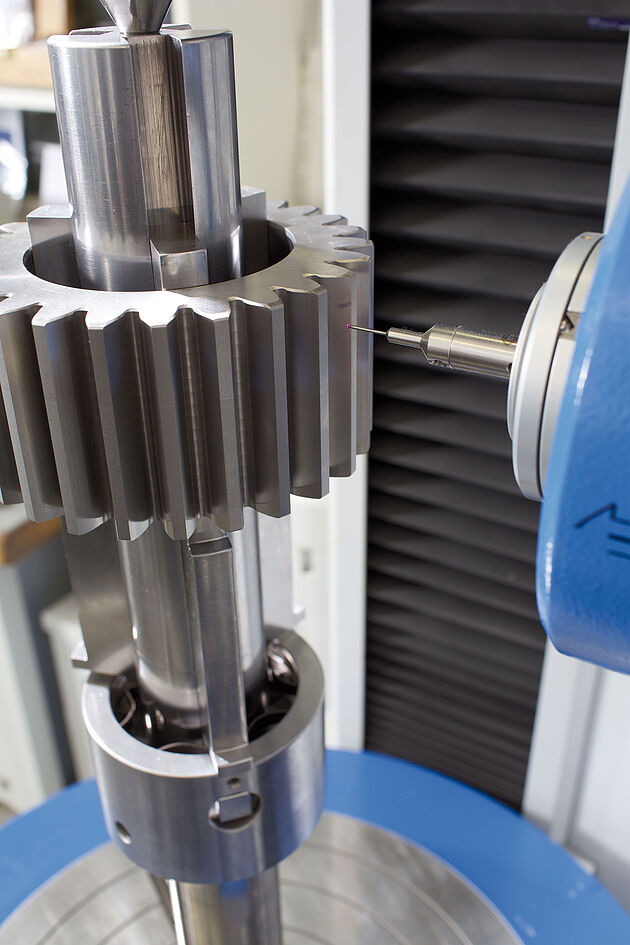

The Hänel quality system is supported by the very latest testing and measurement technologies in our air-conditioned inspection department:

KLINGELNBERG-HÖFLER P 26 and P 40 precision CNC measuring centers for automated testing of profile, alignment, pitch and concentricity deviations as well as surface quality. The 3D coordinate measurements are made on a MITUTOYO STRATO-Apex 776. Double flank rolling is tested on the HOMMEL ZWG 8305 and HÖFLER ZW 300. A programmable MAHR HEIGHT MEASURING DEVICE is available for length and cross-sectional testing.

Surface testing is performed on a HOMMEL-TESTER T 8000 with documentation unit. KB 250BVRZ is used to check hardness.