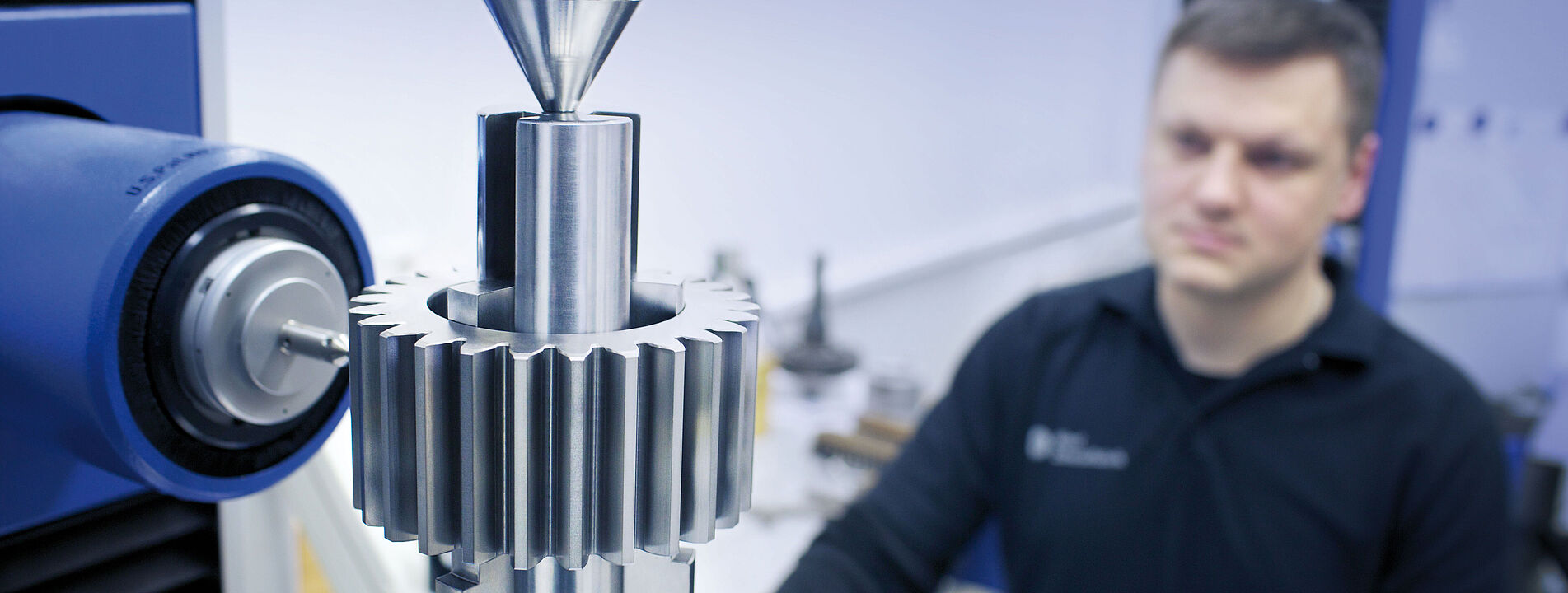

Precision is a tradition at Hänel

Precision and quality are the foundations of our good name

Our state-of-the-art machinery offers us and our customers a wide range of production options. In conjunction with our specialists, it is the basic prerequisite for manufacturing accurately and efficiently.

The Hänel portfolio of precision gears:

Milled spur gears up to 400 mm diameter and 275 mm tooth width. Ground spur gears (Reishauer) up to 400 mm diameter and 180 mm tooth width. Module range from 0.5 to 8. Diametral pitch range from DP 48 to DP 5.

Turning

Turning

The preparatory work is the foundation for subsequent precision.

More

Turning

The preparatory work is the foundation for subsequent precision.

By using the latest MAZAK CNC machining centers with portal loaders, we achieve high efficiency while maintaining consistently high production quality.

At the heart of our turning department are five MAZAK lathe centers with power tools and loading systems:

MAZAK MULIPLEX W200Y-SmoothG

MAZAK QUICK TURN 250 MSY

MAZAK MULIPLEX 6200 Y with loader

MAZAK MULIPLEX 6250 with loader

MAZAK NEXUS 250 II 1000

Plus one precision hard turning machine:

HARDINGE QUEST 10/65 SP

Gear cutting

Gear cutting

The gears are cut on ultramodern CNC hobbing machines.

More

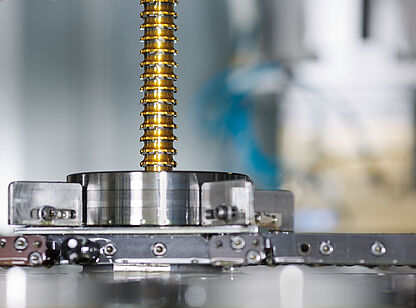

Gear cutting

The gears are cut on ultramodern CNC hobbing machines.

We have no problem meeting the highest quality requirements for cylindrical gears and gear shafts thanks to our state-of-the-art production technology. Automatic loading systems help us to achieve maximum efficiency which is reflected in an excellent price/performance ratio.

LIEBHERR gear hobbing machine LC 300

Gear milling

GLEASON-PFAUTER GP 300 ES

CNC gear shaping machine with electronic helical guide

GLEASON-PFAUTER P 210 L

CNC hobbing machine with Felsomat loading system for gear shafts

GP 200 CNC hobbing machine with

64-point loading magazine for cylindrical gears

Koepfer K300 CNC solution

KOEPFER 200 CNC hobbing machine with integrated portal loader

Here you can find more information on the subject of gear cutting

Internal broaching

Internal broaching

In addition to the horizontal broaching machine, a high-speed hydraulic vertical broaching machine with loading system is also available for broaching keyways.

More

Internal broaching

In addition to the horizontal broaching machine, a high-speed hydraulic vertical broaching machine with loading system is also available for broaching keyways.

A wide range of precision tools ensure consistent production quality while guaranteeing a high degree of flexibility.

KARL KLINK High-speed hydraulic vertical broaching machine with loading system for soft and hard broaching

RAUSCH RW 6/1250 Horizontal broaching machine

Internal cylindrical grinding | Surface grinding

Internal cylindrical grinding | Surface grinding

The latest production equipment for finishing is indispensable if the highest quality demands are to be met.

More

Internal cylindrical grinding | Surface grinding

The latest production equipment for finishing is indispensable if the highest quality demands are to be met. Our technology meets these demands in full, observing shape and position tolerances as well as providing consistent quality.

OKAMOTO GRIND-X CNC surface grinding machine

REINECKER ISA 103 CNC high-performance grinding machine with integrated mini-robot loading system for medium to large quantities

STUDER S 141 CNC high-performance internal cylindrical grinding machine with turret holding up to four grinding spindles for top quality demands with maximum flexibility

VOUMARD 110 CNC with Fanuc control

External cylindrical grinding

External cylindrical grinding

The finishing of gear shafts and cylindrical gears is carried out on state-of-the-art CNC external cylindrical grinding machines.

More

External cylindrical grinding

The finishing of gear shafts and cylindrical gears is carried out on state-of-the-art CNC external cylindrical grinding machines.

We meet the most stringent quality requirements, particularly in the production of pump shafts and gears.

Loaders enable us to achieve maximum productivity while ensuring a consistently high level of manufacturing quality.

Studer S 33 CNC universal external cylindrical grinding machine with WeStep automation cell

STUDER S 36 CNC universal cylindrical grinding machine with Felsomat load system, for internal and external grinding

STUDER S 33 CNC universal cylindrical grinding machine

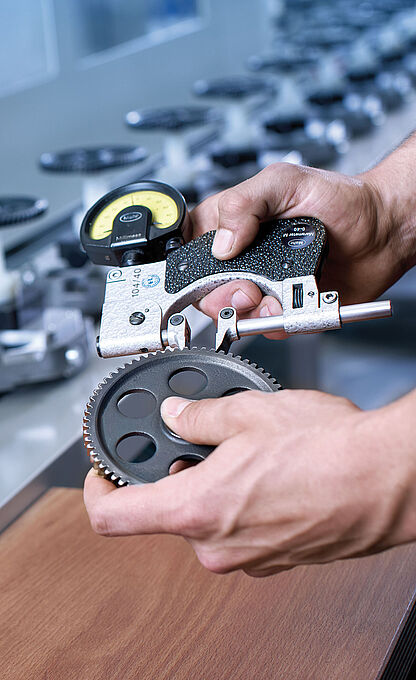

Profile grinding of gear teeth

Profile grinding of gear teeth

The precision machining of tooth profiles for workpieces up to 400 mm in diameter is carried out on high-performance grinding machines.

More

Profile grinding of gear teeth

The precision machining of tooth profiles for workpieces up to 400 mm in diameter is carried out on high-performance grinding machines.

Specifications up to DIN Quality Level 4 are handled as a matter of course.

The use of the latest CNC technology enables us to obtain a high degree of flexibility which also allows special solutions with regard to noise optimization.

Thanks to our employees’ wealth of experience and our use of the latest production technology for finishing, we are well equipped to handle any task.

The centerpiece of our machine shop:

1 REISHAUER-CNC-RZ 260 with RL3K loader

1 REISHAUER-CNC-RZ 362 A

1 REISHAUER-CNC-RZ 400 with Felsomat loader

1 HÖFLER-HELIX 400 KK Cylindrical gear grinding machine

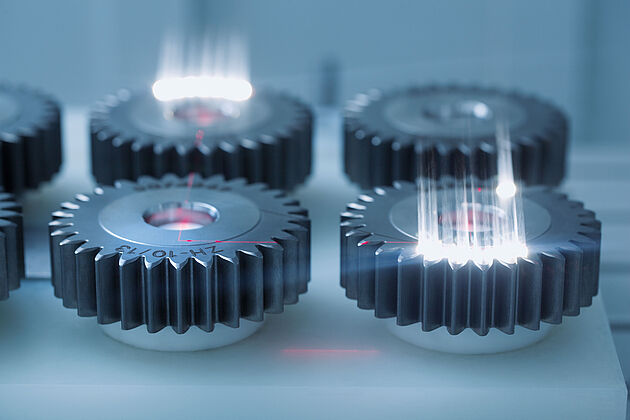

Laser marking

Laser marking

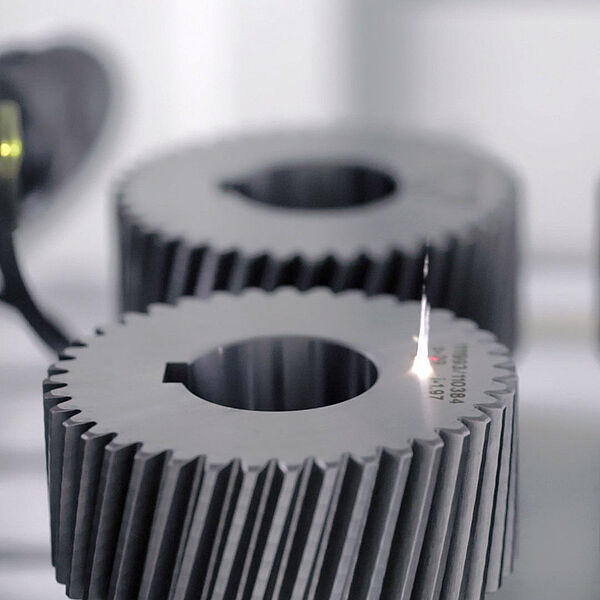

The Hänel quality assurance system is supported by the latest laser and engraving technology. The laser marking system gives each Hänel gear a unique identification according to customer specification.

More

Laser marking

Each gear is unique!

The Hänel quality assurance system is supported by the latest laser and engraving technology. The laser marking system gives each Hänel gear a unique identification according to customer specifications.

High-tech laser marking system:

TYKMA ELECTROX Model EMS 400

Products

Products

Cylindrical gears, milled angular helical gears, flank waves with slip-on gears...

More

Products

| Products | Sectors | |

|---|---|---|

|

Ground cylindrical gears straight / oblique / conical |

Module 0,5 - 8 Max. diameter 400 mm Tooth width 180 mm Quality up to 4 acc. to DIN 3962 |

|

|

Milled / shaped cylindrical gears straight / oblique / conical |

Module 0,5 - 8 Max. diameter 400 mm Tooth width 275 mm Quality up to 6 acc. to DIN 3962 |

|

| Milled angular helical gears | up to helix angle of 85° Module 0,5 - 2,5 Tooth width 150 mm |

|

|

Flank waves with slip-on gears Profiles acc. to DIN 5480, 5481, 5482, SAE |

Module 0,5 - 4 Tooth width 250 mm, up to total length of 420 mm |

|

|

Broached / shaped tooth hubs / splines Profiles acc. to DIN 5480, 5481, 5482, SAE |

Module 0,5 - 3 Tooth width 60 mm up to pitch circle diameter 85 mm broached up to pitch circle diameter 200 mm shaped |

|

|

Shaped internal gears straight / oblique |

Module 0,5 - 4 Tooth width 60 mm Max. pitch circle diameter 200 mm |

|

| Chain wheels | various pitches up to max. diameter 400 mm |

|

| Tooth belt wheels | various pitches up to max. diameter 400 mm |

|

| Wormwheels | various pitches up to max. diameter 400 mm |

|

| Special tooth gearing | any profiles that can be generated | |

| Piece work / Subcontract work | Gear flank grinding on Reishauer and Höfler |

|