Internal Broaching

We are also well-equipped to perform the internal broaching of workpieces.

Broaching is a production method in machining where a broaching tool attached to a broaching machine is pushed or pulled through a workpiece. This procedure is called internal broaching.

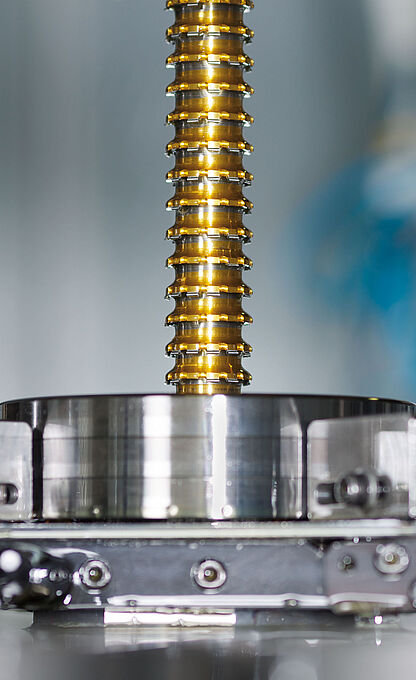

With internal broaching, the broaching tool is pushed or pulled through an existing hole to generate the desired profile for gears.

The tool – usually a broach with multiple blades – is pushed or pulled through the workpiece using a hydraulic vertical or horizontal broaching machine. This creates a cut profile in the workpiece that corresponds to the shape of the broach.

Depending on requirements, broaching can be rectangular, hexagonal or another profile.

High-precision internal gearing, such as gearing according to DIN 5480, is possible. We offer all standard internal broaching profiles, including keyways and general profiles according to DIN and ISO standards.

We primarily use profile broaches for smaller-diameter internal gearings. This is a much faster method than using gear shaping for internal gearing. Broaching creates the necessary internal profile – generally with only a single stroke. It is ideal in cases where maximum efficiency and precision in manufacturing are required.

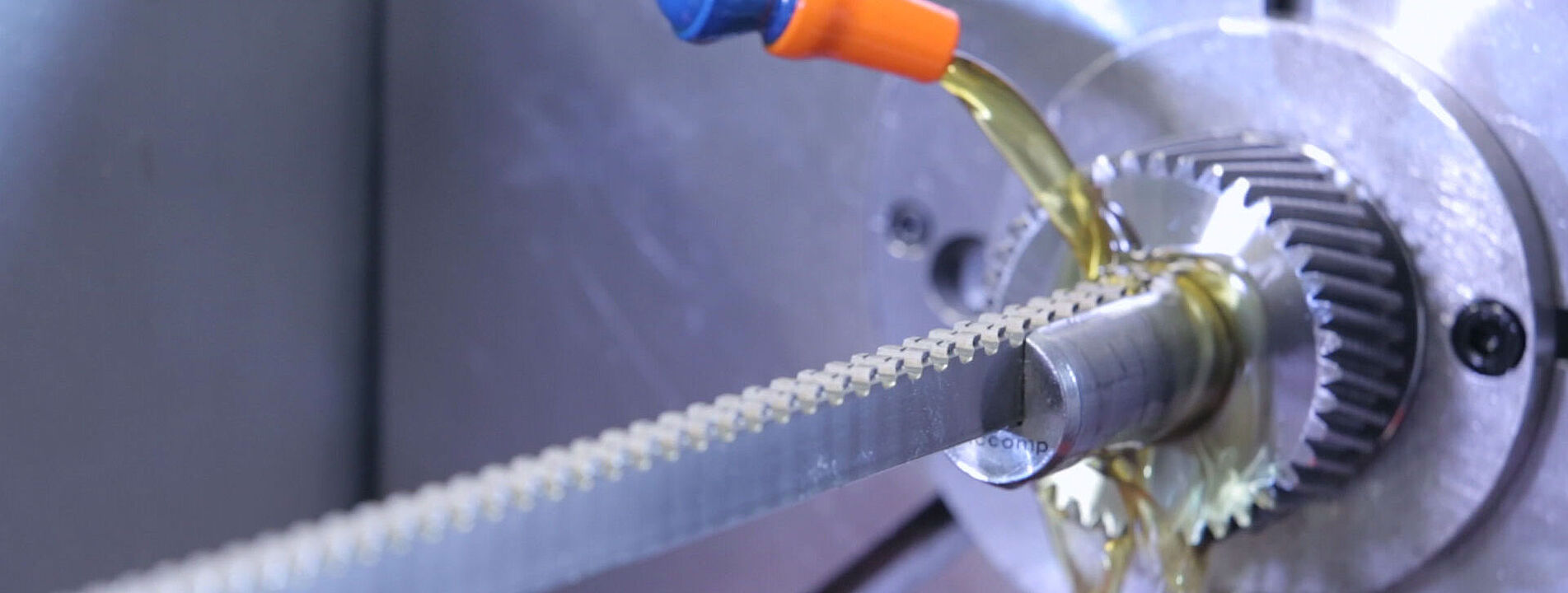

Internal gearing can also be “finish-broached” in its hardened state. The tool that is generally used for this hard broaching is made of a high-strength, coated material, usually carbide. The broaching tool is again pushed or pulled through the existing internal profile and guided by very precise tool holders. The broaching tool’s carbide blades remove any profile errors or deviations that occurred during hardening processes. Such equalization substantially improves the quality of the internal profile. This procedure is also called calibration broaching.

In addition to a high-speed hydraulic vertical broaching machine with a loading system, we also have a horizontal broaching machine for broaching keyways according to DIN 6885.

Our wide selection of precision broaching tools ensures consistent manufacturing quality and a high degree of flexibility.

We use the following broaching machines at our production site:

KARL KLINK high-speed hydraulic vertical broaching machine with loading system for soft and hard broaching

RAUSCH RW 6/1250 horizontal broaching machine

Feel free to contact us company at any time if you have any questions or need more information about processes in production engineering and broaching. We will be happy to advise you!