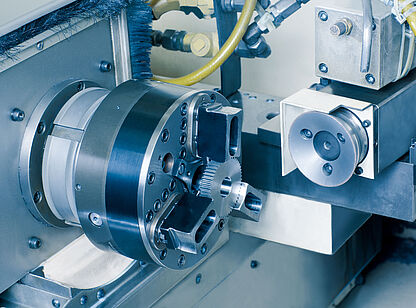

Surface Grinding / Internal Cylindrical Grinding of Workpieces

We are also ideally equipped to perform the internal cylindrical grinding and surface grinding of gears.

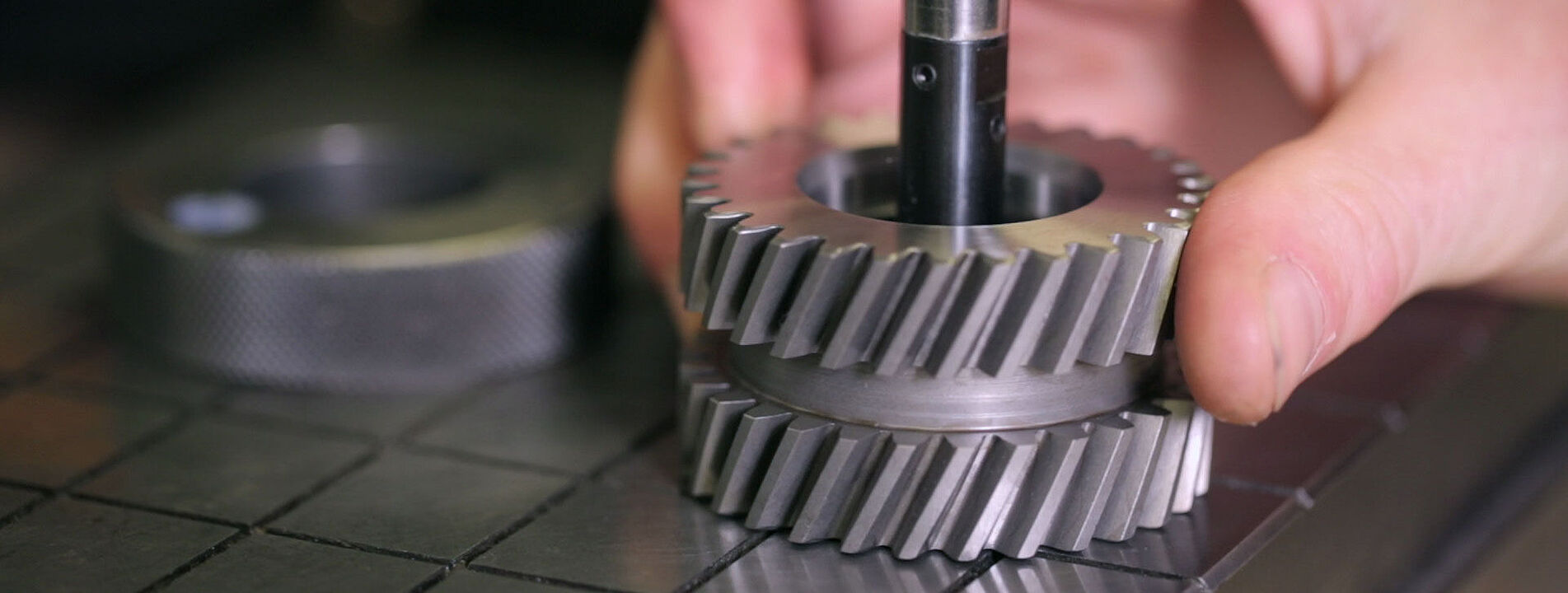

Our surface grinding and internal cylindrical grinding machines are perfectly designed to machine gears, pinions, cylindrical gears, ring gears and pump gears. The high-precision internal cylindrical grinding and surface grinding of workpieces using state-of-the-art CNC grinding systems guarantees the highly precise functioning, long service life and quiet operation of the gears we produce. These machining steps set the stage for each component’s subsequent precision and functioning.

Our technology for CNC surface grinding and internal grinding meets these requirements in terms of shape and position tolerances as well as consistent quality of workpieces.

Gears that we grind on our internal cylindrical and surface grinding machines are most frequently used in gear unit manufacturing and drive engineering.

The deployment of fully-automated loading systems for internal cylindrical grinding as well as high-precision tools also allows us maximize productivity and flexibility while maintaining consistently high production quality.

Even complex and rush jobs are easily done, thanks to cutting-edge CNC technology for internal cylindrical grinding.

Our surface grinding and internal cylindrical grinding machines can process components up to an internal diameter of 250 mm.

Due to the geometry, surface grinding and internal cylindrical grinding create a large contact surface between the grinding wheel and the gear, which means that the grinding processes are extremely sensitive to thermal damage. That’s why we use porous, vitrified-bond grinding components with a coarse grain and low hardness, such as diamond and corundum tools that we precisely dress for the surface grinding or internal grinding production process. Depending on the surface finish required, we use specially prepared grinding wheels.

In order to prevent structural changes, thermal distortion and cracking of the base material’s surface, internal cylindrical grinding is performed as wet grinding using the appropriate coolant.

You expect excellent results from us. And we deliver with maximum quality and maximum precision at maximum speed!

We also offer up to Quality 4 according to DIN as standard in the areas of internal cylindrical grinding and surface grinding.

At Hänel Precision Gears, we grind workpieces on high-quality CNC machines. For example, we use the following grinding machines in our processes:

OKAMOTO GRIND-X CNC surface grinding machine

REINECKER ISA 103 CNC high-performance grinding machine with integrated mini-robot loading system

STUDER S 141 CNC high-performance internal cylindrical grinding machine with turret holding up to four grinding spindles

VOUMARD 110 CNC with Fanuc control

Feel free to contact us at any time if you have any questions about surface grinding and internal cylindrical grinding processes.

Our employees will be happy to advise you.