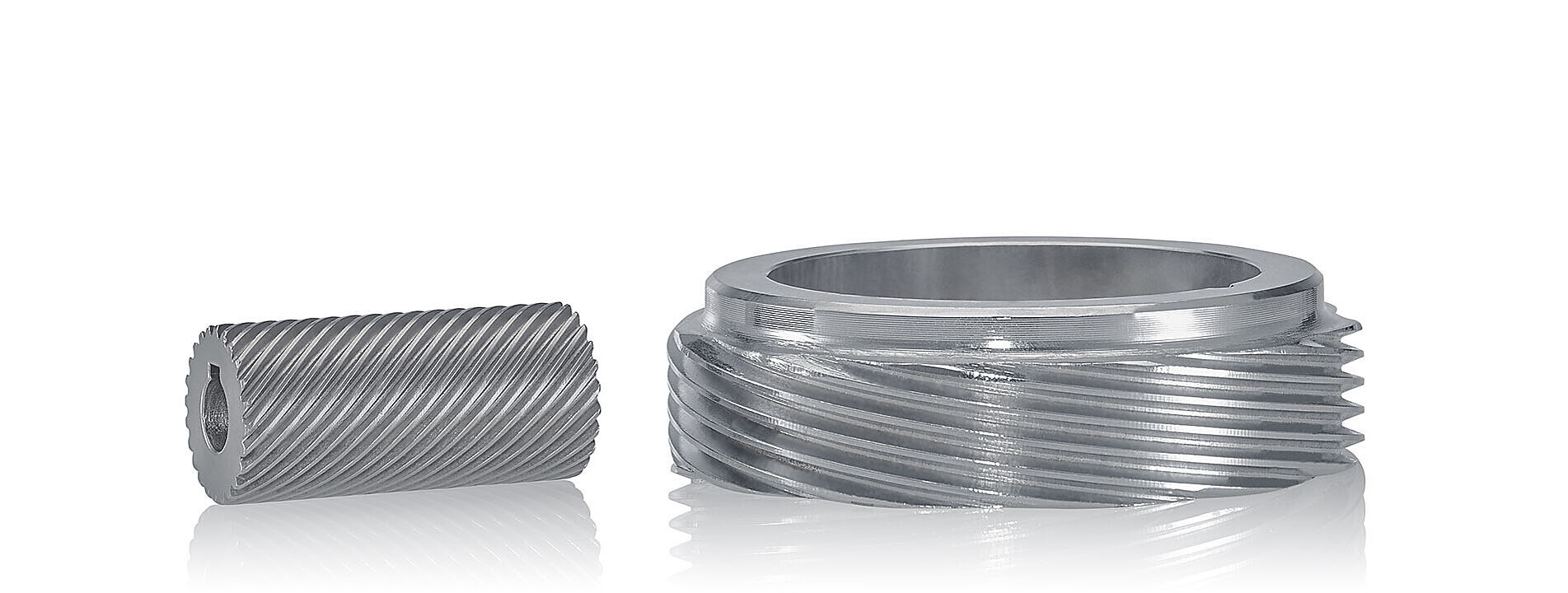

Helical Gears

Helical gears are also known as diagonal spur gears or screw gears. They are spur gears with angular teeth. They are mounted on shafts in parallel or crosswise at an helix angle of up to 90°.

These gears are installed in helical gear drives, which are mechanical, positive locking gearsets. The driveshafts in helical gear drives have a skewed orientation. In other words, the driveshafts in the helical gear drive are neither parallel to one another, nor do they have a point of intersection like the axis of a bevel gearset. Unlike worm gear drives, in which the driveshafts are also skewed, the helical gear drive is equipped with helical gears on both axis. This configuration results in a lower gear (transmission) ratio.

When rolling off in a fashion similar to screw threads, the teeth of helical gears touch at one point only. This contact at the involute of the gear teeth makes the helical gear drive better suited for the transmission of smaller forces rather than larger ones. A maximum transmission ratio of 1:5 is possible.

The constant sliding friction between the meshing teeth of helical gears can result in faster wear. This issue can be resolved through the use of additives in the lubricant.

The advantages of helical gearsets include very smooth operation and low noise levels. In applications having a constant increase or a constant decrease in the transmission of power, the paired teeth engage gradually. Thanks to this special meshing, the transmission of torque is smoother with helical gears as opposed to gears that do not have diagonal teeth.

Another advantage of spur gears with diagonal teeth is the possibility of shifting them in relatively wide ranges without compromising the transmission power. Both gears in helical gearsets can also be installed within a wide range of skewed configurations to each other. In such cases, however, it is important that the diagonal teeth of the meshing helical gears are pointing in opposite directions. Like screw threads, the teeth of helical gears can be skewed to the left or to the right.

For this reason helical gear drives with diagonally meshing spur gears are preferred for controlling purposes. Helical gearsets are also typically used in manual gearboxes to send signals from driveshafts to speedometers.

Helical gears are usually manufactured from case-hardened steels, cast iron or brass.

Thanks to our modern high-tech machining processes, we offer our customers a wide range of manufacturing services. In addition to these efficient precision processes, Hänel specialists have many years of experience in making high-quality gears.

We will be happy to advise you and demonstrate our expertise in gear machining processes. We can manufacture the high-precision gears you need. Feel free to contact us!