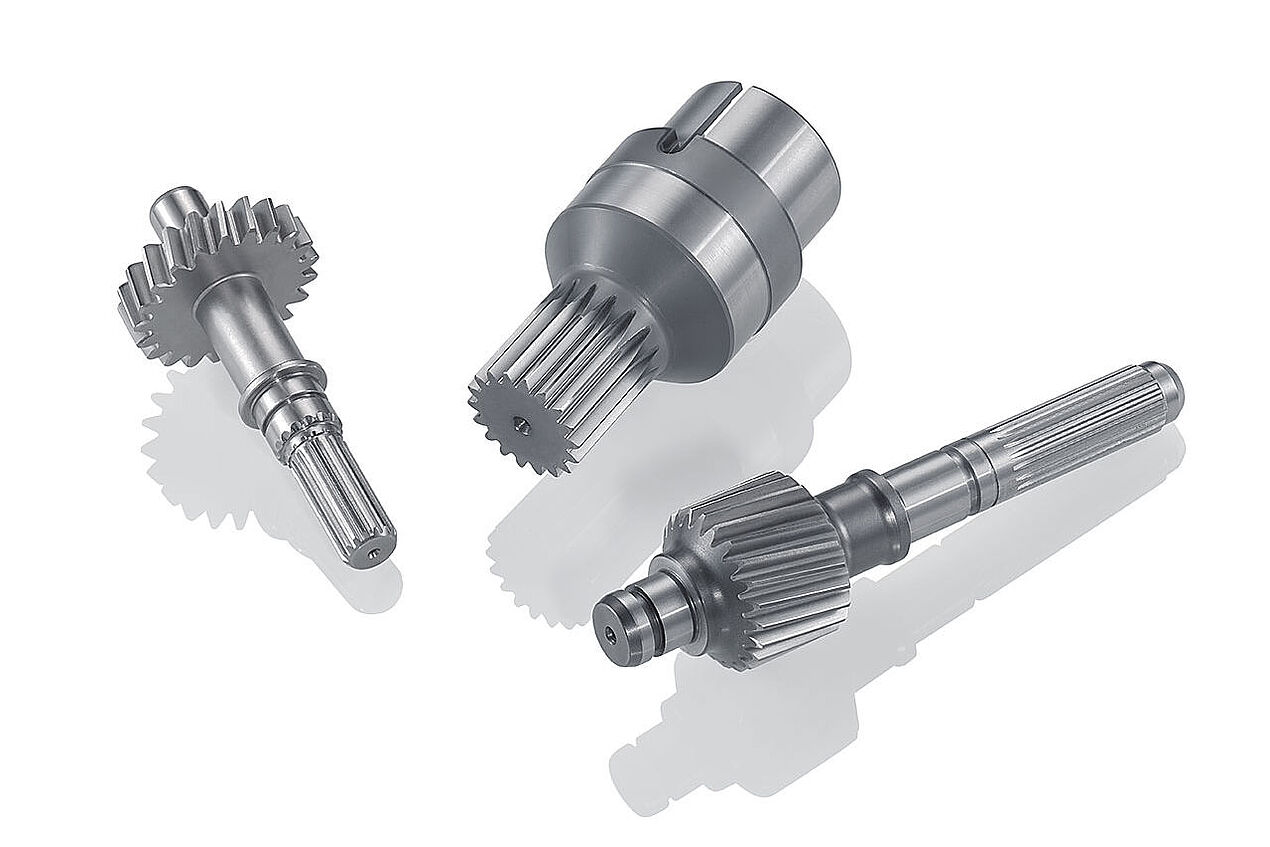

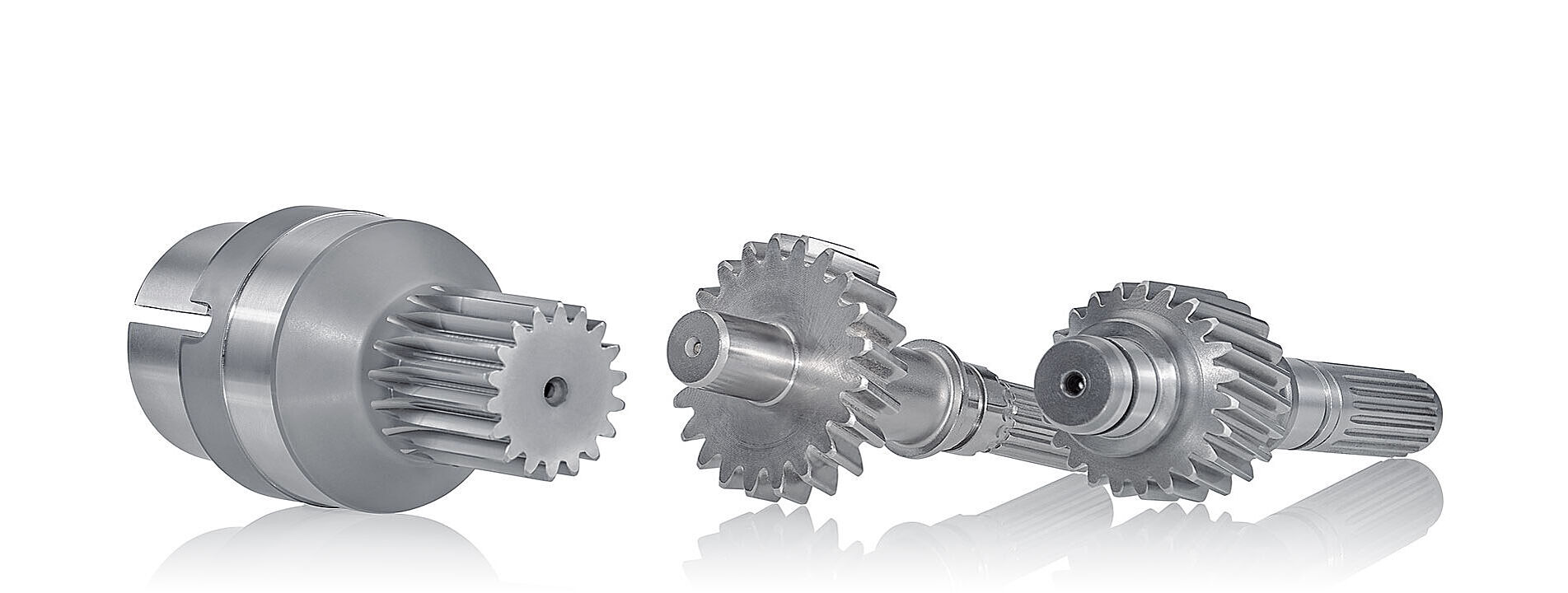

Pinion Shafts

A pinion shaft consists of a pinion machined directly onto the drive shaft in a gear unit to form a single component. The pinion on the pinion shaft is the smaller gear (spur gear) in a gear unit and usually serves as a drive gear. The gears in a gear unit often take the form of a pinion shaft because of the transmission ratio at high torques and the small size of the pinion shaft. This makes it possible to extend the utilization limits and increase the resource efficiency of conventional processes using pinions.

Thanks to the pinion shaft’s small space requirements and high performance capability, it is the solution of choice for transmitting torques in the automotive and aerospace industries as well as in general engineering.

For manufacturing pinion shafts up to a length of approximately 420 mm, we use high-precision, premium CNC gear-cutting machines from Gleason-Pfauter and Köpfer. Various gearing types are possible, such as pinion shafts with splines according to DIN 5480 or running gears according to DIN 867.

Additional gearings can be manufactured to meet specific requirements, both individually and position-specific, using the high-precision touch probe system of modern CNC gear-cutting machines.

To meet extremely precise quality specifications, we perform the hard-fine machining of gearing on state-of-the-art gear flank grinding machines from Reishauer and Höfler. On the basis of this manufacturing technology, we are able to produce components with shape, position and surface roughness characteristics that meet quality specifications, and at the same time we guarantee that the prescribed surface quality and profile accuracies are fulfilled.

The discontinuous profile grinding method is often used to manufacture pinion shafts. This process makes it possible to model various profile shapes and tooth modifications on the gears. It also enables the machining of materials like steel, aluminum, various non-ferrous metals and plastic. To ensure that the pinion shaft has the necessary stability under load, its mating component is generally manufactured from the same material as the pinion itself.

The ultra-fine finishing of the gearing of Hänel Precision Gears pinions is carried out on high-performance grinding machines having a diameter of up to 400 mm. Our gears meet quality requirements up to Quality 4 according to DIN. Thanks to the latest CNC technology, we achieve a high degree of flexibility in gear production. With our state-of-the-art manufacturing technologies for pinion shaft finishing and our many years of experience, we are ready to satisfy a wide range of customer requirements.

Schedule an appointment – there is no obligation – and let us demonstrate our expertise in flank and profile grinding. We look forward to hearing from you! We can produce high-precision pinion shafts that meet your specifications.