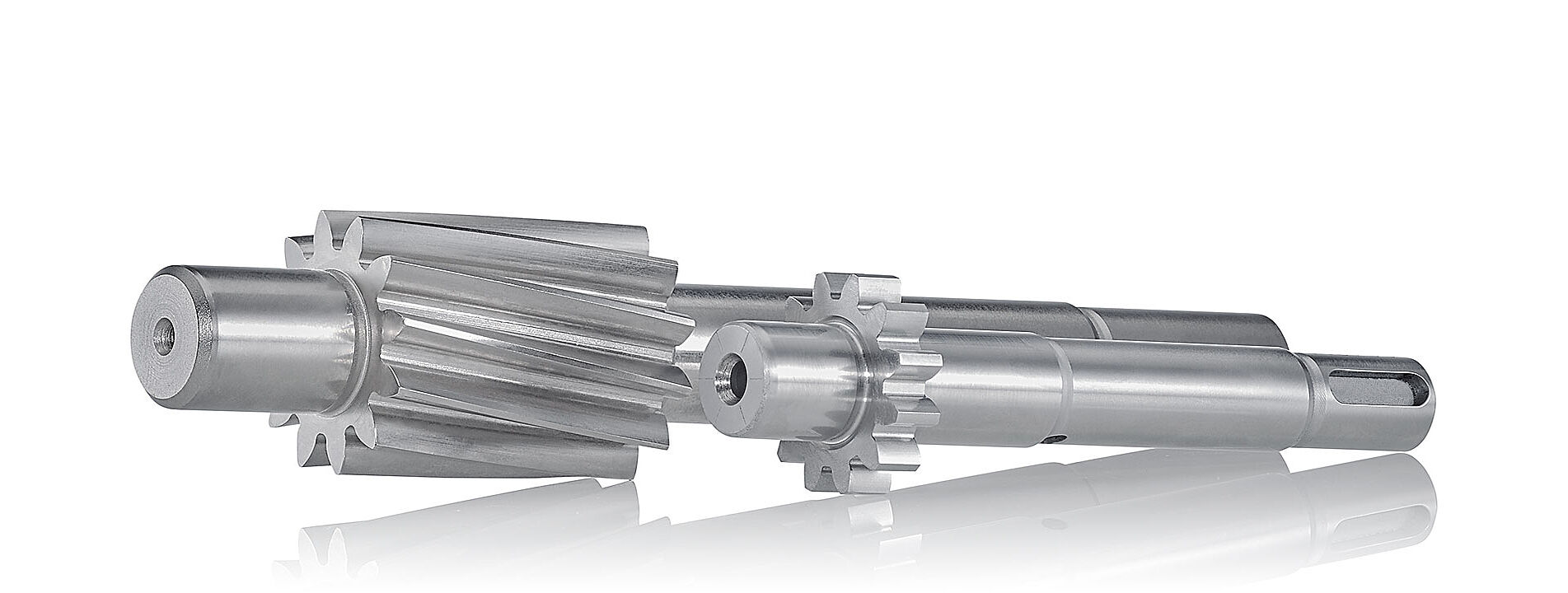

Pump Shafts

The function of pump shafts

Pump shafts are generally used in feed pumps. Depending on their design, feed pumps can pump various liquid media under pressure. Because of the different requirements for leakproofness, these pumps require precision-made, highly accurate gearing that is predominantly hardened and has been ground with maximum precision. Pump shafts are a central component of feed pumps (also called gear pumps) and are connected to the motor shaft via the inlet and sealing shafts. They transmit the rotary motion from the motor to the pump gearing.

The feed pump is made up of a drive shaft and a rotating pump shaft. The rotation of these shafts generates pressure in the pump for pumping the liquid media. These media can be low-viscosity liquids like fuels, or high-viscosity liquids like those used in the chemical industry.

The medium and the amount of medium to be pumped ultimately determine the size and material of the pump shafts in the pump.

The pump’s performance requirements also determine a gear shaft’s material and gearing. For many applications, pump shafts undergo high stress due to heavy loads, high pressure and high speeds, and the material is subject to extreme loads. This is why precise specifications and the highest-quality pump components are required in manufacturing. The composition of the liquid to be pumped determines the metallurgic factors that apply when manufacturing the pump shafts.

Other bases for assessing pump shafts include reliable shaft deflections, maximum torque to be transmitted, and possible lateral and torsional vibrations. When selecting the shaft material, it is important to consider that pump shafts are subject to extreme wear and must be corrosion-resistant.

Basic environmental conditions can wear down many types of metal, and exposure to aggressive chemical liquids can also cause corrosion and damage to the pump components. Stainless steel is corrosion-resistant and is ideal for manufacturing pump shafts with a longer service life and above-average performance. Corrosive media in particular have a tremendous impact on gears in pumps. Also, changes in temperature must not permanently alter the pump’s delivery rate over the course of its service life.

Thanks to our high-precision manufacturing systems and professional tools for gears, we can produce pump shafts that are precisely tailored to your requirements. Gears are professionally manufactured in our factory using state-of-the-art CNC machines.

Thanks to advanced processes for gear production and our many years of experience, we have no problem meeting the highest requirements for quality when manufacturing gear shafts. Using automatic loading systems in the production of our gears, we achieve maximum cost-efficiency that is reflected in an excellent cost-benefit ratio.

When it comes to gear manufacturing, we have the high-quality tools and machines needed to handle every order. With the latest CNC technology, innovative CAM software and state-of-the-art milling procedures, we can flexibly respond to our customers’ individual specifications and easily implement even highly complex, custom manufacturing solutions as required.

Schedule an appointment – there is no obligation – and let us demonstrate our expertise in gear manufacturing. We look forward to hearing from you! We can produce high-precision pump shafts to meet your specific requirements.